Predictive modelling

Using predictive modelling to manage microbiological shelf life risks

Smartfood R&D has been a specialist in predictive microbiology (predictive modelling) for over two decades. Predictive modelling takes mathematical calculations to predict the behaviour of micro-organisms in foods and determine the shelf life of products or map the microbiological risks in advance.

In predictive modelling, we distinguish between predictive modelling of recipes and predictive modelling of processes.

Using predictive microbiology, we can even go back in time. We refer to this as predictive modelling in reverse. This allows us to establish the cause of microbiological complaints in retrospect, for instance.

Predictive modelling based on recipes

Based on a recipe and information about the production process, we calculate the microbiological shelf life of your final product within five working days.

Our recipe-specific and process-specific calculation matrices have been validated through challenge tests using relevant micro-organisms selected from our in-house strain collection. Recipes modulated by smartfood R&D are now marketed worldwide.

The results of the calculations are elaborated in a clear report, which also includes advice on possible adjustments to a recipe, the standards to be applied during production, and other practical recommendations.

We help companies – be they start-up companies or multinationals, and anything in between – to develop a brilliant product concept into a realistic, scalable recipe for which all microbiological risks are identified in advance. Predictive modelling allows us to examine the feasibility of an idea at an early stage. Identified risks are thus preventively reduced to significantly increase the likelihood of a successful product launch.

Predictive modelling processes

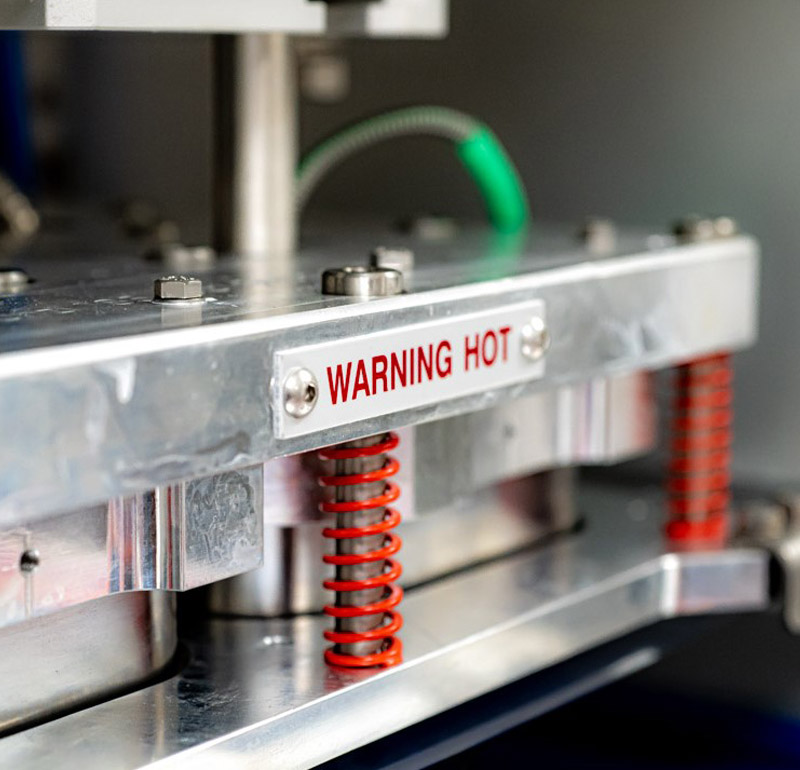

Predictive modelling in heating processes is a discipline in itself, which boils down to temperature and time. But how do you decide where and how temperature and time must be measured, and what other factors play a crucial role in the effectiveness of heating processes? Smartfood R&D uses high-quality calculation models to assess the effectiveness of both pasteurisation and sterilisation processes with a high degree of precision.

Higher production efficiency through optimisation of pasteurisation processes

Using real-time temperature-time recordings, we are able to accurately map the effectiveness of pasteurisation processes. We regularly see that the time required for the heating process can be reduced by optimising the temperature gradient during the process. A shorter pasteurization process results in a permanent increase in production efficiency because less moisture evaporates from the product, for example.

Savings on scheduled investments

We regularly consult with clients about scheduled investments in new or existing production lines. Our knowledge of predictive modelling also comes in handy when estimating in advance whether investing in a process will yield the desired results.

By linking predictive modelling and specialist microbiology to scheduled investments, we have helped to save clients tens of thousands of euros in investments.

View our other services

Accelerated shelf-life testing

Microbiological, physico-chemical and sensory shelf-life testing accelerated by a factor of up to 10.

Predictive modelling

Predictive microbiology is the initial step in substantiating the shelf life of your product.

Challenge tests

Challenge tests using pathogens and non-pathogenic micro-organisms for any product and process.

Industrial microbiology

Custom precision microbiology carried out in-house for each industrial production process.

Process Validation

Validation of processes for the effective control of microbiological risks.