Industrial microbiology

The role of micro-organisms in food production processes

Industrial microbiology requires specialist knowledge of microbiology combined with expertise in validating production processes. We study the behaviour of micro-organisms in various production processes involved in the food industry on an ongoing basis, specifically scrutinising parts of the production process where microbiological food safety risks may occur. Examples include cutting blades, washing water, wind tunnel fans, boilers, sprinkler systems, brine baths and packaging areas.

Certain conditions in the production process may unintentionally stimulate the growth of micro-organisms. Using our specialist knowledge, we analyse the effect of measures in the production process to prevent the undesired growth of micro-organisms. We thus focus on the optimum design of the production process to reduce or eliminate the risk of growth of unwanted micro-organisms.

Micro-organisms are constantly on the move

We distinguish an unmistakable trend in an increasing resistance of vegetative micro-organisms to preservatives and an increase in resistance of spores of spore-forming bacteria to heating processes, and we assume that this trend will continue. We are closely monitoring this trend and adjusting our calculation models for predictive modelling where required.

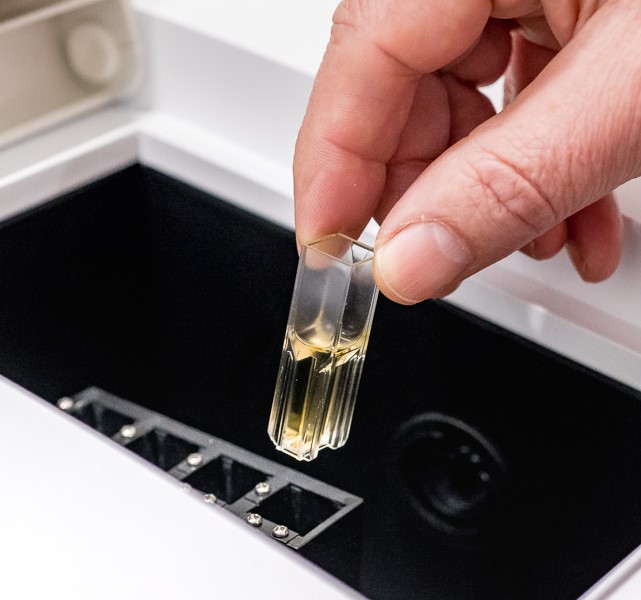

Smartfood R&D provides the option to further identify micro-organisms found using Maldi-Tof analysis.

These techniques allow us to establish the exact name of the bacterium that has started growing. Using this information,

we can identify and solve microbiological spoilage and food safety risks with even greater precision.

Troubleshooting

Irrespective of our expertise in microbial risk management, certain shelf-life issues or product deviations remain, an underlying cause for which cannot be easily identified.

We support companies that find themselves confronted with these complex cases by providing troubleshooting; a service that involves the systematic identification and analysis of potential causes for the problem. Using our microbiological expertise and specialist knowledge of production processes, we develop innovative insights for our clients.

Solutions often turn out to be astonishingly easy

In some cases, working the other way around is preferred and in these cases we start by naming the micro-organisms we find. Once we have established the micro-organism we are dealing with, we can pinpoint the exact location where the contamination is likely to occur in the process.

This allows us to map out where the problem occurs, why it occurs there and what (microbiological) mechanism underlies it. After identifying these factors, in most cases it is amazingly easy to solve a shelf-life issue. If you would like to know more about how we arrive at targeted advice for complex puzzles like these, feel free to contact us or come and visit. We are happy to tell you more!

Validation of processes requires a combination of precise knowledge and measurement: you must know what needs to be measured and this measurement has to be done very precisely. In this context, we would like to quote deceased Dutch footballer Johan Cruijff:

“football is simple, but playing simple football is one of the most difficult things to do".

View our other services

Accelerated shelf-life testing

Microbiological, physico-chemical and sensory shelf-life testing accelerated by a factor of up to 10.

Predictive modelling

Predictive microbiology is the initial step in substantiating the shelf life of your product.

Challenge tests

Challenge tests using pathogens and non-pathogenic micro-organisms for any product and process.

Industrial microbiology

Custom precision microbiology carried out in-house for each industrial production process.

Process Validation

Validation of processes for the effective control of microbiological risks.